About Fomra Group

In the industry since the year 1939.

Fomra group of companies traces its roots back in the year 1939. Then, Mr. Motilal Fomra, had begun the company which primarily dealt in south India and made it a petroleum and electricity giant in that era.

Mr Madhav Das Fomra, the grandson of Motilal Fomra, has made a name for himself and his company in the field of Metal Treatment & Construction of commercial and residential complexes. Mr. Madhav Das Forma first began his venture with "Gopal & Fomra Nitriting" In the year 1992 which deals in Metal & Surface treatment . The First liquid nitriding treatment in eastern India. Then in the year 1996 he ventured in the field of construction and found an astounding success. Today Fomra Builders Pvt Ltd has built numerous residential complexes which has provided shelter to Five Hundred (500) Number of families.

Company Mission & Vision

Its Foundation is on Strict Moral Values

Fomra Group of companies has built its foundation on strict moral values. The three pillars of the foundation on which the group stands are:

- Faith: Because being responsible for the betterment of others is a huge morale booster.

- Future:Because it’s just not dwelling in the glories of the present, but making sure that the future is better too.

- Fortune: Because once you enter your dream home fortune is bound to follow you.

Story behind the logo

The Blue in the Fomra's logo stands for Trust and Responsibility. We all know Blue symbolizes the sky and the ocean. But it also signifies the youthful spirit, sincerity and inspirational creativity and such characteristics go well with the Fomra Group.

The color White doesn't need any special introduction. We all know it signifies Peace, Purity and Wholesomeness, something that relates to the Fomra Group. Not to forget White stands for Faith & Brilliance, something the name 'Fomra Group' has meant for decades.

Ever thought what the letter ‘F’ meant in the Fomra’s logo?? It just doesn’t stand for Family, Fortune and Future only. We are your Friend and we always help our Folks. Have Faith on us, because we provide the Fascinating Facilities that too at a Fair price. We are totally Focused on Fulfillment of your dreams. And quite Frankly, it's our Fearlessness to Face any situation that makes us a Fantastic /Folks to work with. Now, isn't that Fabulous, our ventures are always Fruitful and along with us you too shall Flourish. That's how we become your Family. So let's put some White & Blue in your life. Make Fomra Group your trusted partner. Go for the "F".

Businesses

Click for more details

Real Estate

Real Estate

500 numbers of customers have been satisfied and grown with us. As we believe in respecting your dreams and fulfilling it.

Click for more details

Metal Treatment

Metal Treatment

We are the FIRST to introduce Liquid Nitriding in EASTERN INDIA. We started back in the year 1992.

Click for more details

Hospitality

Hospitality

As they say that you find peace near the river 'GANGA' that's where our Guest House is. Moti Bhavan is present with personal ghat.

Real Estate

The real estate industry is a highly competitive industry.

Not only are there loads of stiff competition, but at the same time, there are commitments to be met and dreams to be fulfilled. And that’s where FOMRA group of company stands apart from the rest.

Fomra Builders Pvt.Ltd being an innovative and dynamic construction company has always fulfilled the dreams of all people in search of their 'Homes Sweet Home'. It's because, we at Fomra Builders Pvt.Ltd value your dreams. Being a construction company that adds values to your dreams in INDIA is not easy. But in Fomra Builders Pvt.Ltd, we not only commit, but we make it real. Having a rich and experienced 17 years of industry exposure is not a cake walk. It came on tough sweat and at the end of these years we can proudly say "Thinking Beyond Reality".

Completed Projects

Five Hundred number of satisfied families have been staying in our projects and after they succeeded more in their life as because we do all our projects according to Vastu as we believe in vastu and our vastu man is from South Indian.

Satya Apartment

Is being built to perfection, creating a haven that is safe and secure, convenient and luxurious.

190, Lake Town, Block – B, Kolkata 700 089.

Fomra Tower

Where dreams come alive.

84A, A.J.C Bose Road, Kolkata – 700 014

Satya Regency

Satya Regency, the latest address for your dream home. We tried to provide you with most of modern facilities. It is close to City's two's elitist club namely Tollygunge Club and Royal Calcutta Golf Club.

94, Buroshibtala Main Road, Kolkata

Satya Residency

Satya Residency is being constructed On Freehold land and situated on Chetla Road, very close to Rashbehari, Kalighat Temple, metro.

14, Chetla Road Kolkata

Satya Vakita

We Fomra Builders Pvt.Ltd, welcome you at our dream project i.e SATYA VATIKA. We tried to provide you with most of modern facilities and luxurious for least cost.

149, Raja Rajendra Lal Mitra Road, Beliaghata

Satya Niwas

Satya Niwas is being built to Perfection, convenient and luxuries. We tried to provide you with most of modern facilities for least cost.

243, Lake Town, Block – B, Kolkata – 700 089.

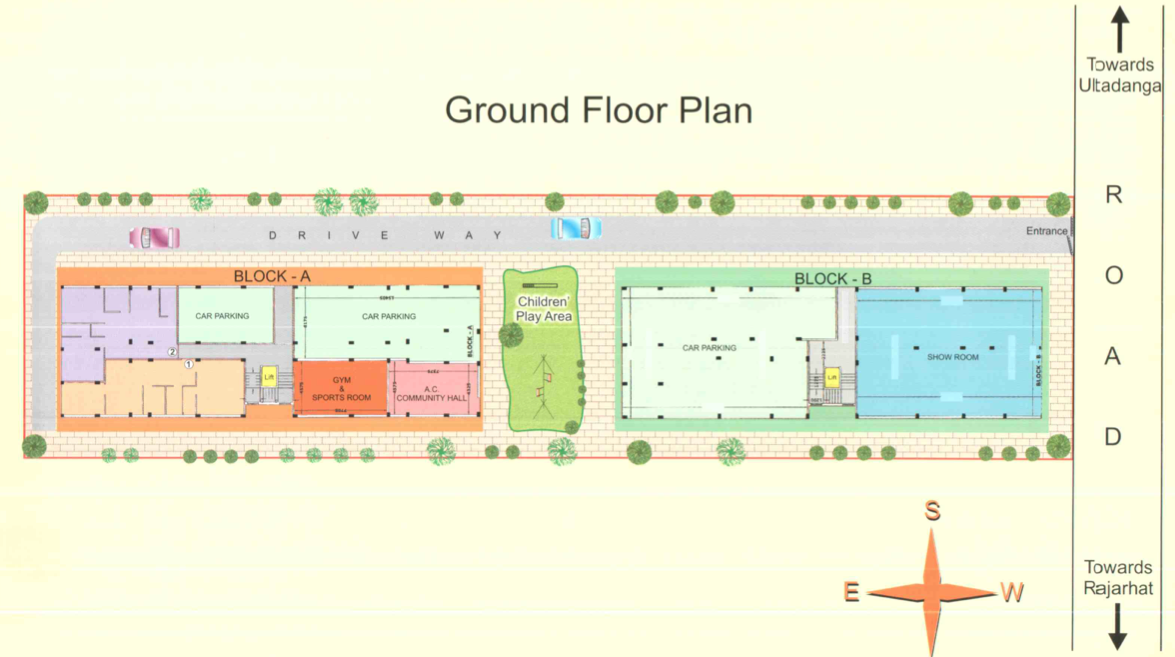

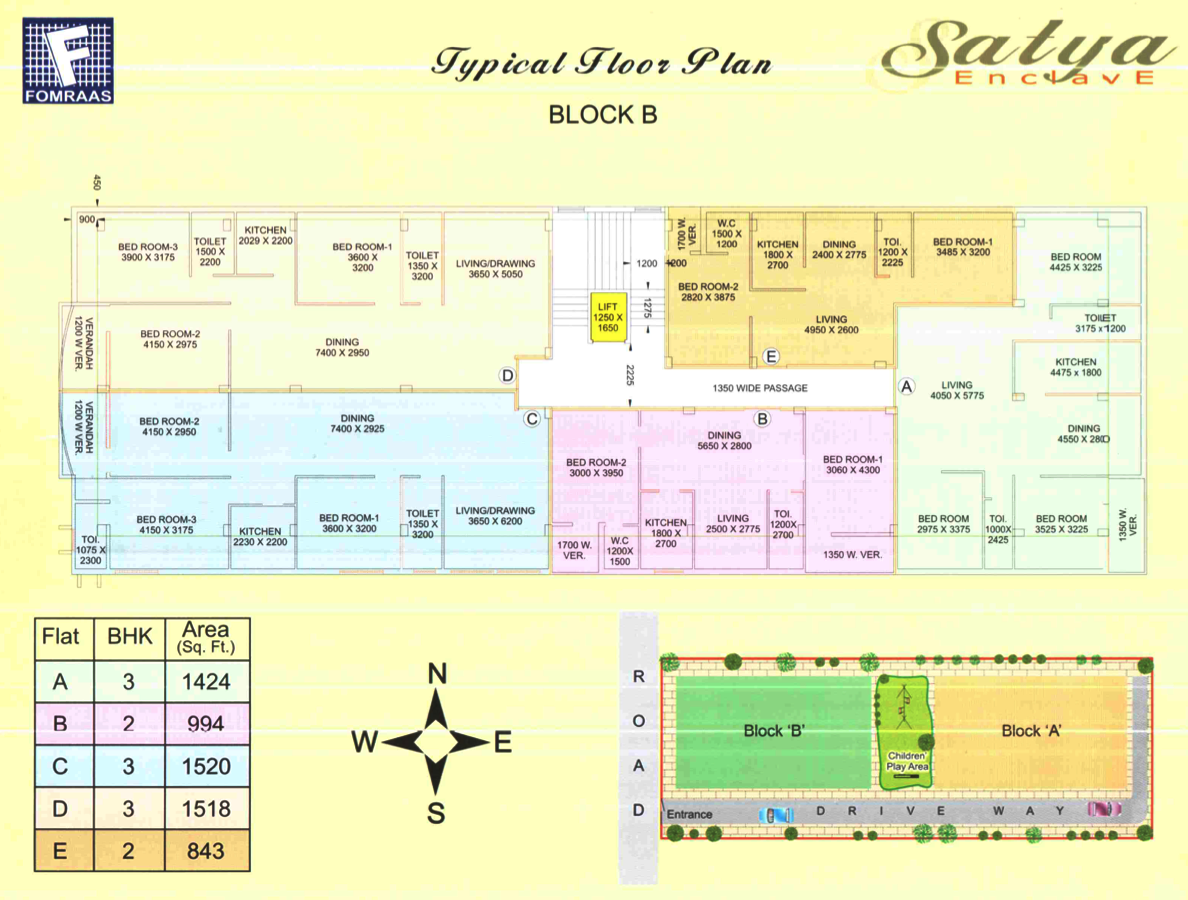

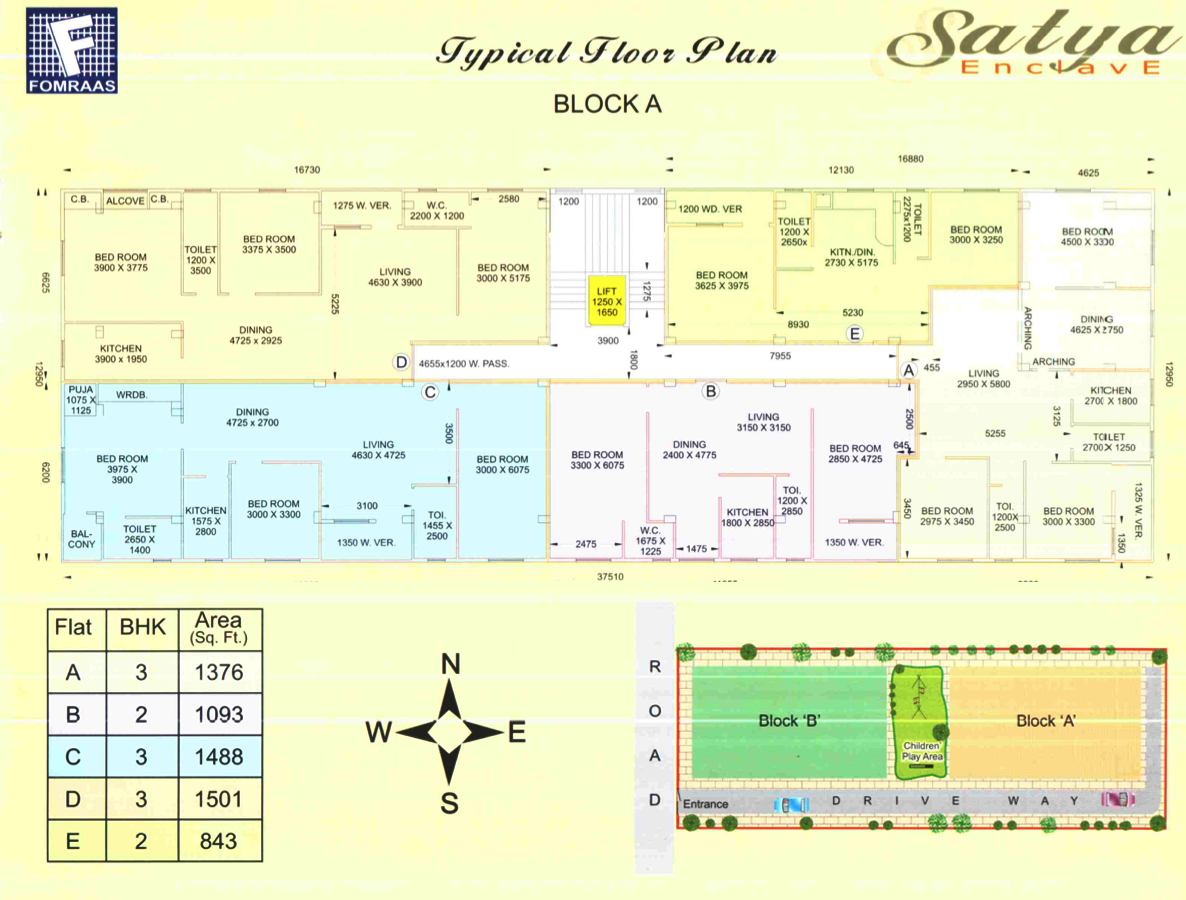

Satya Enclave

Most Promising construction underlying in 2015

We, Fomra Builders Pvt.ltd, welcome you at our dream project, i.e SATYA ENCALVE. We can fill reams of paper in writing about us that we are this, we are that. But that doesn't count. It is the performance that matters only. So we better believe in performing. We know only your satisfaction can make us proud. Satisfaction about construction, material, facility and above all value for price.

Satya Enclave is being built to perfection, creating a haven that is safe and secure, convenient and luxurious. We tried to provide you with most of modern facilities and amenities for least of cost. You will surely like to share this enjoyable atmosphere with your near and dear. Location is very ideal, as it is situated where future kolkata is coming up. It is open, environment friendly, eye-soothing, close to all-important place like, New town, Sector V, City Center II, Airport, Hospital, Bank, Parks, Water Parks etc. one of the most important feature is connectivity as VIP Road and Rajarhat Express Way take only few minutes to connect you to the main city.

So, we hope you will surely find your home at satya enclave very close to your dream and wish you all the very best.

Marketed By

Somani Realtors Pvt. Ltd. One of the fastest growing Real Estate Marketing Company spread over from the extreme frings of North-South-East-West kolata & Greater Kolkata.

Contact Details

Contact Person: Rudresh Fomra Contact Number: +91 98301 39700

Creek Row

Address: 38A, Creek Row, Kolkata.

Details coming soon!

Metal Treatment

Gopal & Fomra Nitriding

Non pollutive sulfur accelerated Nitriding and nitrocarburising process.

Nitriding process solves problems of wear, scuff seizure, fatigue and corrosion of ferrous meterials like steels and cast irons.

Nitriding process helps you to bring down warranty claims and customer satisfaction.

Nitriding process helps you to bring down warranty claims and customer satisfaction.

Nitriding also greatly reduces costs because of short treatment times. Nitriding is applied to fully finished and ground componentsas it is distortion free. It can hence be advantageously utilised to replace cyaniding, carboNitriding, gas Nitriding and carburising.

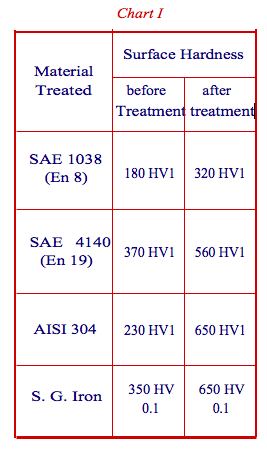

Materials Treated By Us

CARBON STEELS ■ ALLOY STEELS ■ HIGH SPEED STEELS ■ STAINLESS STEELS ■ CAST IRONS INCLUDING SG IRONS

The Process

Temperature of operation 560 ° + 10 °C

There are three separate salts needed for operation of Nitriding

- Base salt NC4 used for making up new baths and also to maintain the working bath at a constant level by means of periodic additions.

- Regenerator salt NC2 used to regenerate the bath and maintain & constant Nitriding potential.

- Potassium sulphide(K2S)added regularly in very small quantities to maintain the non pollutive nature of the bath and improve the metallurgical properties of parts treated in it.

Properties of Nitriding Treated Parts

Properties of Nitriding Treated Parts

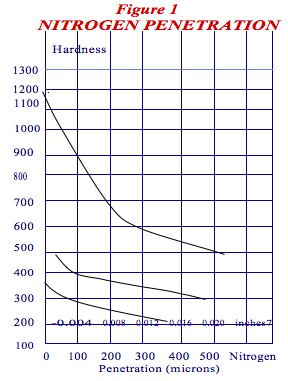

Increase in Nitriding Hardness the compound zone and the less is its thickness.

The higher the carbon and alloy contents of the surfaces treated the higher is the hardness of the surface layer.

Relation between hardness & depth of nitrogen penetration of steels treated at 570'C for 2 hours.

- EN8 (SAE 1038)

- EN19 (SAE 4140)

- H 11 Die Steel

Metallography of Nitriding Layers

Nitriding process produces a combination of a very hard compound zone of epsilon and the diffusion zone. The higher the carbon and alloy content of the substrate, the more compact is the compound zone and the less is its thickness. The sulfur produces a unique porous surface layer.

Decrease In Frictional Power Loss

Nitriding reduces coefficient of friction of treated surfaces. This results in reduced frictional power loss under identical conditions and contributes to increased fuel economy.

Increase In Wear Resistance

Increase In Wear Resistance

Resistance to adhesive and abrasive wear is increased enorously by Nitriding process. The wear resistance is better than other treatment processes like phosphating, gas Nitriding case hardening etc. as given in Fig. 2

Increase In Scuffing And Seizure Resistance

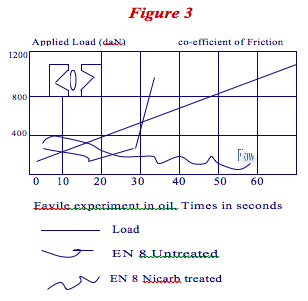

The sulfur compounds present in the surface layers inhibit 'metal to metal' welding and facilitates 'running-in'. Hence it completely eliminates problems of scuff and seizure (Fig. 3)

The sulfur compounds present in the surface layers inhibit 'metal to metal' welding and facilitates 'running-in'. Hence it completely eliminates problems of scuff and seizure (Fig. 3)

Figure 3

Increase in Fatigue Resistance

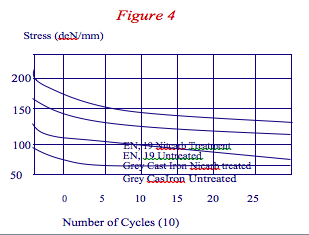

Nitriding gives rise to residual compressive stresses on the Nitriding which increases the fatigue strength of treated components. (Fig. 4)

Nitriding gives rise to residual compressive stresses on the Nitriding which increases the fatigue strength of treated components. (Fig. 4)

NUMBER OF REVOLUTIONS, log scale Amaler tests with 20 kg load on 0.15% C steel test pieces subjected to various treatments using SAE 30 oil as lubricant.

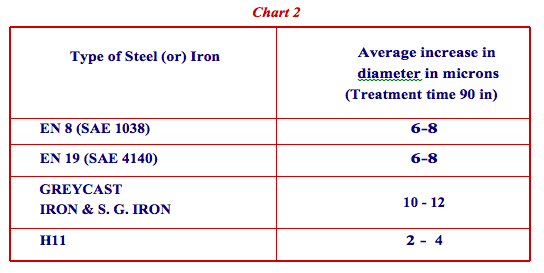

Dimensional Change

Nitriding treatment gives rise to a uniform growth of components, this being independent of the shape and position in the bath during treatment, but differing in magnitude depending on the composition of the material (Chart-2)

Prerequisites For Components To Be Treated By Us

The component to be treated by Nitriding should have been earlier stress relieved or tempered at a minimum temperature of 580C for 3 hours minimum.

Typical Components Treated By US

- Crankshafts

- Camshafts

- Cylinder liners

- Valves and Valve guides

- Timing gears & spockets

- Rocker Arm Shafts

- Bearing cages

- Flanges

- Bushes

- Shafts & spindles

- Slides & guides

- Cylinder blocks

- Front fork tubes

- Railways components

- Plastic machinery screws & barrels

- Hydraulic components Mining machinery components

- Aluminum extrusion dies

- Metal working tools

- High speed steel eating tools

- Defence Components

- All ferrous materials & its alloys.

Hospitality

Moti Bhavan, Haridwar

Careers

Coming Soon!